COOLING TOWER SOFTWARE AND CONSULTING

SERVICES

Over 65 years of service to the evaporative cooling industry

COOLING TOWER SOFTWARE - COUNTER FLOW AND CROSS FLOW

PSYCHROMETRIC PROBLEM SOLVING SOFTWARE

COOLING TOWER CONSULTING SERVICES

EVAPORATIVE AIR PRE-COOLERS FOR AIR COOLED HEAT EXCHANGERS

TECHNICAL PAPERS BY DESJARDINS

COUNTER FLOW AND CROSS FLOW COOLING TOWER

THERMAL PERFORMANCE PREDICTION PROGRAMS

The crossflow and counterflow thermal design programs are based on the Cooling Tower Theory presented in CTI technical paper TP92-01. Use of standard CTI Merkel Theory can result in designs that under-perform, sometimes by as much as 15% to 20%. For many years it was known that the simplified Merkel Theory often needed a “hot water correction factor” or that there were errors or too many “simplifications” in the theory. These deficiencies have been confirmed by many official CTI field tests. Hallet, Pritchard, Lefevre, Bentley and other members of the CTI “Non-Merkel Theory” committee presented many theories. It was concluded that any theory that has results with excessive “scattering of the test data points” justifies a better theory. Initial analysis using standard CTI type Merkel Theory programs of test data collected by EPRI at their test facility showed considerable scatter of the test points. Actually it was found the data was very accurate, and it was the cooling tower theory that needed to be corrected. It was necessary to uses higher quality calculus integration and psychrometric equations, a realization that the enthalpy of the water film around a drop of water is not the same as the enthalpy of the bulk water temperature in the middle of the water drop so the enthalpy driving force may be less than originally expected, the Lewis Number is less than 1.0, evaporation needs be considered, and it might be necessary to provide adjustment factors based on air velocity for some fills. Clients have reported our “offset” theory corrects for these problems, and apparently when compared to other programs such as the MRL program even with its “Merkel Correction Factor” may result in better performance prediction. As one old time cooling tower executive said: “The object is to make the points line up, not necessarily in a straight line on log-log graph paper, but at least on a smooth curve even when considering different air rates or nozzle pressure.” If the theory is good when you put the test data in, and the points line up, then you should be able to get reliable results when you take the data out and use it to design your tower.” Our programs also include quality fan and pressure drop data that may be different than some data presented by optimistic fan manufacturers that do not use practical tip clearance and fan cylinder design.

EXAMPLES OF DESIGN THERMAL RATING PROGRAMS:

These programs were originally written to “catch the cheaters”. There were many old towers that did not meet the required performance with a resulting significant loss to the users. At the time many power plants purchased towers with penalties of as much as $1 million a degree for missing performance, yet confirmation testing by the CTI still had a lot towers that did not pass the tests. Some of it was due to applicable theory as discussed above, and some of it was due to market competitive actions.

Since then the programs have been revised to be practical design tools. Performance and pressure drop data on fills, fans, drift eliminators, etc. has been gathered and analyzed from many sources. It is believed most of what is included is very useful. Most fill testing by the sources was run at 100° F. If your design hot water temperature is less than 100° F, or close to it, then use of the standard CTI theory analyzed test data is probably adequate. If it is higher than 100° F then you might see considerable differences, or if you are comparing to actual field test results and the temperatures when the test was made are all very low, then you might get considerable differences when compared to analysis with test data analyzed with the “offset” system. Most fan data is based on model testing and the fan laws are used to adjust for size, speed, density, etc. Some manufacturers fan data must be considered optimistic because they were based on testing in ideal eased inlet cylinders with very close tip clearances. The program allows you to enter a revised total fan efficiency that you would base on your own field testing of those fans, or you could use the charts that are provided to adjust based on actual expected tip clearances.

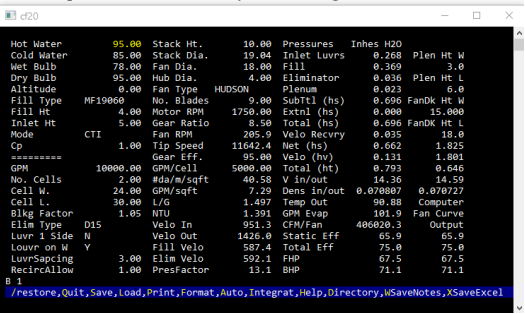

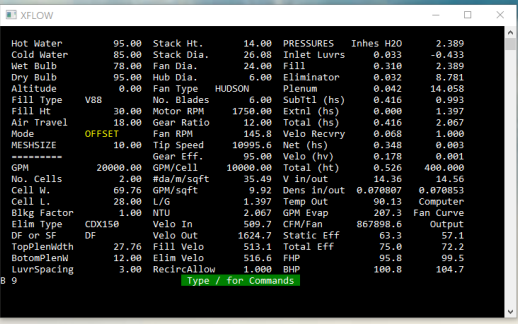

COUNTERFLOW (also available in metric units)

CROSSFLOW

CALCULATE MECHANICAL DRAFT TOWER PERFORMANCE: All of the important design parameters needed to design a cooling tower are shown on one page. Included are data for the most commonly used new tower fans, fills and eliminators. With the built-in on screen HELP function you can access data for many new and old fills and other components simply with entry of their product name. You can thermally analyze existing towers. A detailed operation manual is provided to explain the available fills, fans, eliminators, and to give you guidance towards the most economical tower size and configuration. You can easily change fan sizes, number of blades, fan cylinder heights, tower cell sizes, fill dimensions, gear ratios, fan speeds, and access the help functions for other alternatives. Actual laboratory test data is built in for available fills and eliminators. When raw test data is available for analysis the stored program data input can be based a more advanced “offset” analysis theory.

OBTAIN ACCURATE PREDICTIONS: The program screen is interactive, like a spreadsheet. (You can even Clear it and use it as a spreadsheet.) Design conditions, size of tower and components are input with the aid of individual cell help functions all on one screen. Run the program, and the results are immediately available on the screen. Many built-in guidance and warning messages are actively displayed as the program runs. If changes are necessary you can quickly make adjustments and run again. You do not have to re-enter everything again. If data is available analysis using the “offset” system is possible, otherwise counterflow towers use the standard CTI Merkel Theory and crossflow towers use Zivi-Brand method. Both are modified to include more accurate integration and psychrometric equations and water evaporation effects. Predict performance at any altitude.

ANALYZE YOUR BIDS: Be a knowledgeable buyer. Although the Cooling Technology Institute recommends you test your tower after it is installed to be sure it was designed and built as expected, towers often do not get tested. You can add a degree of protection by checking the predicted performance before you buy. There is even a way to analyze a bid and predict the percentage performance level at the quoted fan power.

EASILY INVESTIGATE ALTERNATE OPPORTUNITIES: Study alternate tower configurations, use the program to estimate the power evaluated cost, or find the best way to up-grade. Investigate the optimum use of fan and pump power as compared to installed capital cost. Use the help screens to be sure the design is within normal design parameters for good air and water distribution, minimum drift and recirculation effects.

PSYCHROMETRIC PROBLEM SOLVING SOFTWARE

Much more than just a data point look-up tool

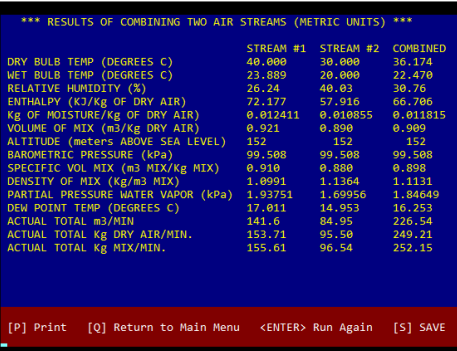

Use it to quickly and accurately step through your process, changing the pressure as you go, as actually happens in the real world, combine air streams, add or remove heat, and quickly solve evaporation or condensation problems. Solve psychrometric and heat transfer problems for air pollution control scrubber systems, HVAC, chemical processes, evaporative cooling with just a few key strokes. No more having to read a single pressure chart until your eyes pop out.

o Combine two air streams using three different types of input.

o Given two known streams - find the combined stream properties.

o If the first and final streams are known - find the missing stream.

o Second stream flow is a percentage of the first stream - find results.

o Add or remove heat from an air stream.

o Find the sensible and latent heat added or removed when given two known points.

o Given a starting point, add or remove latent and sensible heat from an air stream.

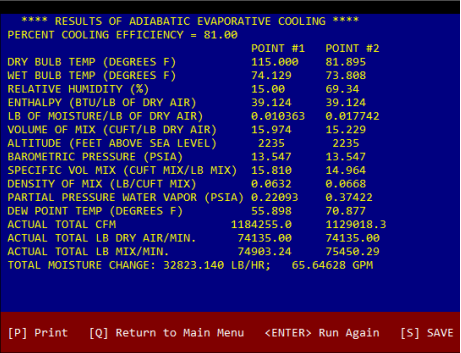

o Given a starting point and "Cooling Efficiency", solve evaporative cooling problems.

Condensation and evaporative heating or cooling calculations are made easy. The amount of water added or condensed is calculated. Flow entry can be in CFM or pounds of dry air or pounds of mix. The psychrometric program calculates the properties of moist air at any elevation to 20,000 feet and for pressures to 35 psia. Temperature range is from -80oF to 2,000oF. Automatically convert to S.I. units.

The Mol Weight and Specific Heat can be revised to allow calculations of properties of other moist gases (such as flue gases). Hot gas scrubbing calculations are made easy.

- The program uses four different pressure input modes: altitude, psia, inches mercury or inches water gage absolute.

- Nine different property input modes are possible: dry bulb - wet bulb; dry bulb - relative humidity; wet bulb - humidity ratio; enthalpy - humidity ratio; dry bulb - humidity ratio; dry bulb - enthalpy; wet bulb - relative humidity; enthalpy - relative humidity; and humidity ratio - relative humidity.

- Given any two of the above properties and a pressure, the other properties are calculated along with three different specific volume options, the dew point temperature, three vapor pressure options, and the density of the mix.

- Toggle your input or results between Metric and IP units.

Easy use: The program saves your last results or inputs to save you time in going to the next portion of your problem. Extensive error warnings help keep you from obtaining false results. Results can be saved to a file for import to a spread sheet or other program for further calculations.

Many companies which no longer have the luxury of having an experienced cooling tower engineer on their staff now use our services. Our client list includes some of the most notable engineer-constructor firms in the world, major power producers, refineries, consulting engineers, developers, tower manufacturers, cooling tower repair firms, and industrial and air conditioning users.

Custom developed thermal rating programs for both counter flow and cross flow towers are used to provide quick, accurate tower performance predictions. Computerized standard specifications are adapted to your unique requirements. It is usually much less expensive to make a computer study than field tests, and while field testing may tell you what your tower is doing now, it does not predict what it will do after you make additions or modifications.

Although we are the leading independent expert in cooling tower thermal performance, we also have 62 years of experience in every aspect of the cooling tower industry from component design of structures, mechanical equipment, and other tower features to practical solutions for citing and installing your tower complete with all the controls and associated equipment.

SERVICES WE HAVE PROVIDED FOR OUR CLIENTS HAVE INCLUDED:

- Bid analysis and thermal performance evaluations

- Specification preparation

- Inspections

- Review for thermal upgrade

- Economic comparisons and evaluations

- Practical review of project needs

- Confidential preliminary tower sizing and budget pricing

- Review material requirements

- Psychrometric, water conservation, and plume abatement problem analysis and design

- Evaporative cooling process studies

- Designs of cooling tower and evaporative cooling sections

- Dry and wet tower economic analysis

- Owner's Representative to monitor thermal performance test

- Thermal performance tests

- Expert Witness

- Technical assistance for attorneys and management

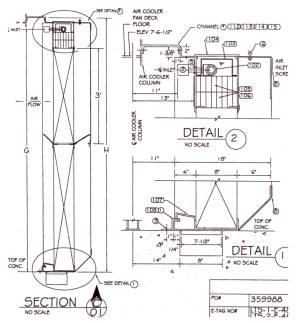

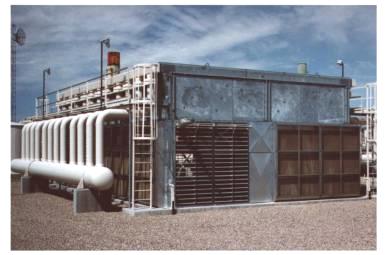

CONSULTING SERVICES AND CONCEPTUAL DESIGN were provided to a geothermal power producer for the 1,556 foot long, 30 fan air cooled heat exchanger shown below. The alternative conventional designs would have had as many as 220 smaller diameter fans to maintain or an A-frame forced draft design that would have been much more subject to air discharge recirculation. CTI technical paper TP16-27 fully describes this unique design.

SOME EXAMPLES OF THOSE WHO HAVE BENEFITED FROM OUR SERVICES

- A major power producer now saves over $300,000 per year because tower performance was up-graded at the time of replacement.

- A repair contractor's fill replacement recommendation was changed to get greater performance for less cost.

- Bid analysis of many proposals revealed possible performance problems, and material and design deficiencies were discovered.

- A specification was developed to encapsulate a failing galvanized steel tower in fire retardant fiberglass, saving the client over $250,000.

- A thermal performance rating program was developed for a major cooling tower repair firm.

- Many specifications have been prepared for refinery and power plant projects.

- Tower repair inspections and construction inspection services have been provided for many projects including specification preparation and thermal performance improvement review.

- Evaporative air pre-coolers have been designed and built for air cooled heat exchangers and turbine air inlet cooling.

- Several turbine inlet air chilling studies have been made, including formal preparation of turnkey bids.

- Plume abatement studies and designs have been provided for several environmentally sensitive projects.

- A complete line of packaged cooling towers was designed for a foreign company including drawings for every part, computerized thermal rating system, inspection of prototype, operation manuals and installation instructions.

- Thermal tests complete with analysis for energy rebates have been provided for high-rise office buildings.

- Expert witness data has been provided for attorneys.

- Complete design and operational analysis of plume abated cooling towers located in noise and vibration sensitive areas.

A COMPLICATED COOLING TOWER

The design of the tower shown above and below included the following:

o Cooling tower thermal performance assessment and design for a 1.3 MW cogeneration central plant retrofit to a 1,000,000 + square foot office building.

o Design parameters for an architectural enclosure and layout to meet existing building space and structural requirements including visual and environmental concerns.

o Plume abatement coil design including by-pass dampers and control system designed to use external heat source for plume abatement and also for emergency heat load dump from the plant generator engine to the coils when the absorption chiller is not in operation. Coils and dampers per API design requirements with conservative fouling factors.

o Fans provided with VFD and controls to assure proper air velocities in the wet section if coil dampers are open or closed. Control system requirements were developed for plume control for all expected atmospheric and load conditions.

o Mechanical equipment selected for noise control to meet city ordinance.

o Vibration isolation of each 2-cell tower. One tower is over an auditorium. Equalization piping designed for hydraulic water balance between the cold water basins of both towers for various combinations of cell operation.

o Fiberglass tower structure and casing with all welded stainless steel cold water basin.

o PVC fill and drift eliminators selected for design conditions and water quality.

o Fire sprinkler system to meet local codes.

o Redundancy of cells and considerations for reliability for different weather conditions, heat loads, and number and types of turbines, engines and chillers running.

o

·

· home

ADIABATIC EVAPORATIVE AIR PRE-COOLERS

|

|

INDUSTRIAL QUALITY FOR AIR COOLED HEAT EXCHANGERS, GAS TURBINES AND INDUSTRIAL BUILDINGS

Evaporative air pre-cooling can significantly decrease your initial capital costs, operating costs, and in some cases allow you to do what otherwise would be impossible. Standard air cooled heat exchangers operate on the dry bulb temperature as the lowest temperature sink for disposal of heat. By using evaporative sections in advance of the air cooled exchanger it is possible to reduce the dry bulb to near the wet bulb temperature by evaporating moisture into the air stream, thus either reducing the amount of surface required, reducing the operating temperature, or increasing the number of hours you can operate at the design dry bulb temperature. Often the use of an air cooled heat exchanger with evaporative air pre-cooling sections can be used where a cooling tower that requires much more year-around water supply would preclude the building of a plant.

We have over 62 years of experience with evaporative cooling equipment. Our computerized sizing system allows accurate design at any elevation and inlet design condition. Our attention to details meets the requirements of the media manufacturer for elimination of leaks, drips, scaling splash-out and proper distribution. Additionally, the distribution of each system design is operated in the factory test unit prior to fabrication of the final product to assure you of a properly functioning field installation.

DESIGN CONSIDERATIONS

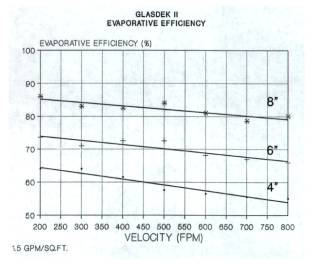

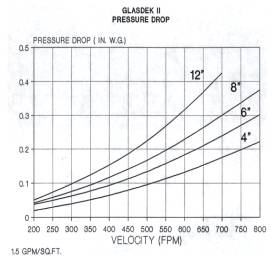

As a standard cooling media we use Munters Corporation Glasdek material. Performance and pressure drop are typically defined as shown in the attached "Efficiency" and "Pressure Drop" graphs with further adjustments made for high altitude applications. For preliminary design investigations please consider that most applications will be economically viable with 6" and 8" thick media operating at about 1.5 gpm per square foot of media plan area and a face velocity of 650 fpm maximum. The maximum net height of each media section generally cannot be more than 10 feet. Applications requiring greater height will require split distribution systems. Standard structures are all welded #304 stainless steel. If you are investigating the use of evaporative air pre-cooling sections please contact us for assistance. We would be pleased to provide you with information on reducing fan power requirements, make-up and blow-down requirements, and where to obtain proper information on water treating and general layout requirements.

"EVAPORATIVE EFFICIENCY" IS DEFINED AS THE REDUCTION IN DRY BULB TEMPERATURE AS A PERCENTAGE OF THE DIFFERENCE BETWEEN THE DRY BULB TEMPERATURE AND THE WET BULB TEMPERATURE.

CUSTOM OPTIMIZED FOR YOUR SPECIFIC SITE CONDITIONS AND EQUIPMENT

|

|

STANDARD FEATURES

o Welded stainless steel frame

o Blow-down fittings

o Glasdek or Celdek media

o PVC pipe manifolds

o Stainless steel air inlet screens

o Double distribution pads

OPTIONAL EQUIPMENT

o Water treatment equipment

o Balance valves collection basin

o Pumps

o Drift eliminators

o Flow meters

o Louvers, doors and panels

WEST COAST ENGINEER:

We investigated several installations and this is the best we have seen

CONSTRUCTION MANAGER:

We installed 40 sections in one day

EVAPORATIVE COOLING WITH FOGGING NOZZLES

We provide design, consulting and supply (though one of our associate companies) of evaporative cooling fogging nozzle systems for large air cooled heat exchangers. These installations require about the same design parameters as listed above for wet surface sections, but the cooling efficiency is limited to about 50% to assure all the water is evaporated. Two distinct advantages are no additional pressure drop and no start-up time required. The designs usually include high pressure pumps, required RO water supply, and controls. Nozzles are high technology to provide very fine fog droplets that are staged to evaporate in only 2 to 4 feet from the nozzle, thus minimizing or eliminating wetting of the surrounding structure, fans and coils. The first cost of this type of system is generally less than wet surface sections, but wind effects can affect the operation, and the parasitic pump power is higher.

TECHNICAL PAPERS BY DESJARDINS

o CTI TP92-01: Using the EPRI test data to verify a more accurate method of predicting cooling tower performance.

o CTI TP06-01: Cooling towers work as a system

o CTI TP08-02: Evaluate your cooling tower

o CTI TP16-27: Use of large diameter fans on air cooled heat exchangers

o Geothermal Resource Council: 50 reasons your cooling tower doesn’t work right

o home

ASK

US. If you have a cooling tower

question, send us e-mail. We will answer it.

Proud Supporter of the CTI

DesJardins

COOLING TOWER CONSULTING SERVICES

RICHARD J.

DESJARDINS

38373 CHERRYWOOD DRIVE

MURRIETA, CA 92562

Cell phone: 760-641-4264

e-mail us: desjardins@verizon.net or coolingtower@verizon.net